Verfügbar ab sofort

Preis auf Anfrage

Bestehend aus:

- Thermoölerhitzer 900 kW

- Gasbrenner mit Gasrampe

- Schaltschrank

- Hauptpumpenstation

- Expansionsgefäss

- Auffanggefäss

Verfügbar ab sofort

Preis auf Anfrage

Bestehend aus:

- Umwälzpumpe

- Motordreiwegventil

- Schaltschrank

- diverse Armaturen

Occasion

Verfügbar ab sofort

Preis auf Anfrage

Thermoölbeheizt

Leistung 350 kg/h / 225 kW

Arbeitsdruck: 2,5 bar

Komplett auf Rahmen aufgebaut.

Occasion

Verfügbar ab sofort

Preis auf Anfrage

Inhalt: 1500 ltr.

Werkstoff: 1.4435

Horizontale Ausführung

Komplett mit Magnet-Niveauanzeige

und Speisewasserpumpe

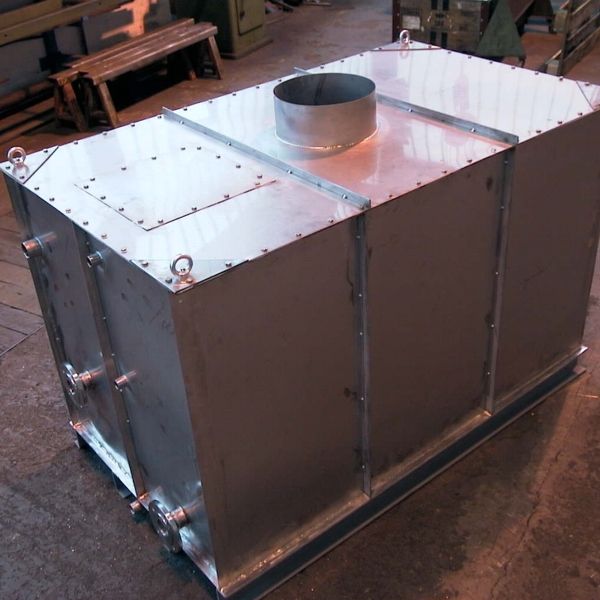

Verfügbar ab sofort

Preis auf Anfrage

Inhalt: 1500 ltr.

Werkstoff: St.

Horizontale Ausführung

Komplett mit Füll- und Entleereinrichtung

Occasion

Verfügbar ab sofort

Preis auf Anfrage

Allweiler NTT 40-250/01/231

43 m3/h 70 mFls

2900 1/min. 15,0 kW

3x400V 50Hz

Komplett zusammengebaut

Markthalle BaselGTS Engineering is also strong in steel constructions such as:

Markthalle BaselGTS Engineering is also strong in steel constructions such as:

- Platforms

- Ladders

- Stairs

- Stair rails

|

|

|

| Markthalle Basel | Platform over a Pool | SBB Betriebe Bellinzona |

Emergency cooling in all performance levels for solid fuel boiler systems, including emergency cooling pumps with diesel engines.

|

|

|

|

Emergency Cooling Pump

with Diesel Engine

|

Emergency Cooler (Outside)

|

Emergency Cooler (Inside) |

Typical emergency cooler as a water basin with a generously sized coil. The cooling of the solid fuel boiler is effected by water evaporating and the resulting steam is discharged directly into the atmosphere.

Automatic thermal degassing and venting of thermal oil systems.

Automatic thermal degassing and venting of thermal oil systems.

Delay Free derived from air and gases from all liquid carrying systems independent of pressure, temperature and flow rate variations. The controller closes on rising fluid level.

Nitrogen equipment for inert gas overlay in the expansion tank.

Nitrogen equipment for inert gas overlay in the expansion tank.

GTS Thermo oil heating systems are generally built as closed systems. The thermal oil in the expansion tank is thereby protected by inert gas (nitrogen) from the atmosphere.

This increases the service life of the thermal oil extreme.

Heat Recovery

Heat Recovery

The high combustion temperatures required for thermal incineration make efficient heat recovery indispensable.

The best way is to recover the heat to a thermal oil heating system.

There are two options:

- To integrate the heat recovery exchanger to a thermal oil system parallel, like a heater.

- To integrate the heat recovery exchanger to a thermal oil system serial, in the inlet pipe before a heater.

Behind the thermal oil exchanger it is possible to install a separate exchanger for Hot water.

|

|

| Heat Recovery | Heat Recovery |

GTS Engineering plans, designs and builds complete control systems and control panels. In a conventional manner with contactor control or PLC

GTS Engineering plans, designs and builds complete control systems and control panels. In a conventional manner with contactor control or PLC

It can only be beneficial if the entire measurement and control technology and the thermal oil plant are from a single source.

|

|

|

| Control Panel (Inside) | Control Panel (Outside) | Control Panel (Inside) |

Page 3 of 7